Starling Cycles UK Owners Ride: April 2024

Aint Nothing Like Good Times And Bike Rides…

At the end of the day, it’s all about riding bikes in the woods. And so, if we can find an excuse to get the community together and go for a ride we’re to grab it with both hands!

And that’s how our Starling Owners Rides came about.

This month we hosted a Starling Cycles Owners Group ride, right here in the UK.

We put a shout-out on the Facebook Owners Group and met up at the awesome Forest of Dean Cycle Centre, AKA Pedalabikeaway.

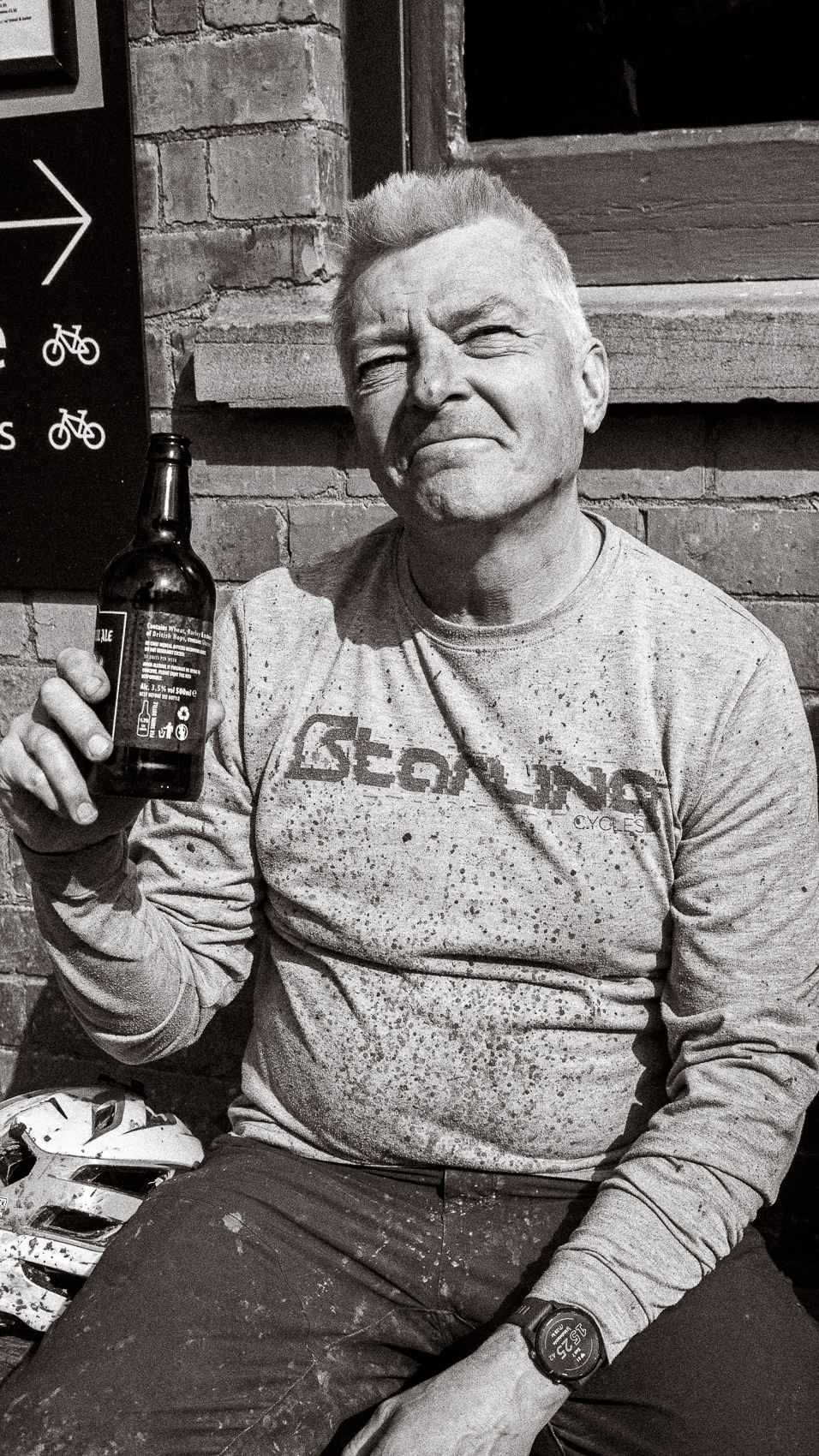

We rode bikes, we drank beers, we made some new friends, we showed off our builds and, most of all, we just had a good laugh in the woods. Exactly what it should be all about.

The day started with a quick talk from Joe about the state of the bike industry, where Starling is at right now and what our plans are for the next year or so. Also about a couple of upcoming new bikes… watch this space for more on those.

And then, we hit the trails around Pedalabikeaway. We made a beeline for those steep, muddy and rooty runs that most of you probably know. They’re the exact trails that Joe designed the bikes for and exactly what he loves to ride. Perfect for our owners ride.

We chipped out a few steep and slippy ones, then nipped back to the Cycle Centre for lunch and a chat.

It was great to see the range of bikes that showed up, and see how a few of our owners like them setup. Poshest bike of the day probably goes to Owner’s Group Big Cheese Rob Williams for his stunning Stainless Murmur that’s dripping in Hope components.

With lunch onboard we bid farewell to a few riders and zipped back up the hill for a few more laps. It was more of Joe’s favourites and we lapped out those Mini-Enduro favourites. Short, steep climbs and some really fun, slippy and sketchy downhills. Perfect stuff.

Once the legs were cooked it was back to the centre for a bit of apres – because what’s a ride without a bit of a social and a beer to wash it down?!

How About Hosting Your Own Owner’s Ride?

We’ve hosted these rides before but with all the busyness of running a business, we’ll admit, it’s been too long since the last one in South Wales. This was our first chance to get everyone together in ages and we’re really keen not to leave it so long next time.

We’re aiming for another Starling Cycles UK Owners Meet in the Autumn, with updates on our mailing list and social.

If you’d like to host an Owner’s Ride in your country, please give us a shout. We’d love to support you, help organise and throw some resources your way. We’d really love to see a whole load of Starling Owners meet up all over the world.

You can join the Starling Cycles Owners Group on Facebook here.

Are you a German Starling Cycles Owner, or Steel Bike Rider?

IronWorkx.De are hosting a Bike N’ BBQ Camp for Starling Riders (but all riders are welcome) May 9-12th. You can find out more here and contact them to register.