Cane Creek Tigon – The Perfect Rear Shock For Single Pivot Bikes?

Cane Creek has recently introduced the Cane Creek Tigon rear shock.

To celebrate the launch we grabbed an in-depth and geeky chat with Sam Anderson at CC. Sam talks Joe through all of the fine details and there wheres, whats and whys of the new shock.

And – we’ve also launched a Ltd Edition Cane Creek Tigon Starling Cycles complete bike, available for Twist and Murmur.

Don’t have time to watch the video? Here’s the short version…

So, the Cane Creek Tigon, what’s it all about? The clue is in the name – half tiger, half lion. Half coil, half air.

Rather than using some meaningless marketing bullshit and saying it gives “the best of both coil and air” I think it’s better to think of it as a coil shock with some extra capabilities.

Let’s take a step back.

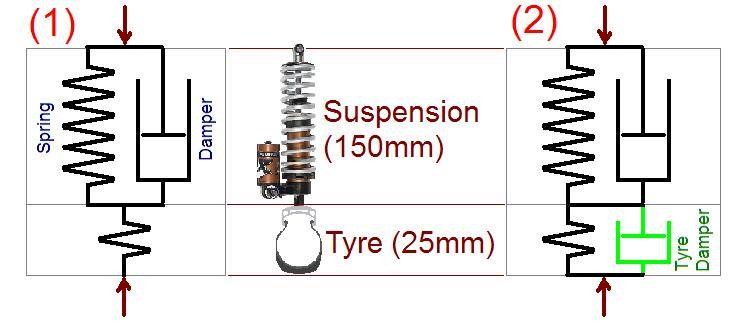

First, are coil rear shocks good for single pivot mountain bikes, and for Starling Cycles?

We actually really, strongly recommend coil shocks for Starling Cycles mountain bike frames. You can read more about that here on our blog about coil shocks and single pivot, steel frames.

Why do we love coil shocks so much? Coil shocks give great early stroke sensitivity resulting in amazing grip. They also provide great mid-stroke support to control chassis shape and provide a platform to push against.

Oppositely, air shocks have some initial friction to overcome. Progressive frame designs have been developed to overcome the negative traits of air shocks. There are plenty of frames out there that are way too progressive, they are so soft at the start, and they don’t ramp up quick enough so they need overly stiff springs to stop them from blowing through mid-stroke travel. And then they ramp up so much at the end you don’t get full travel.

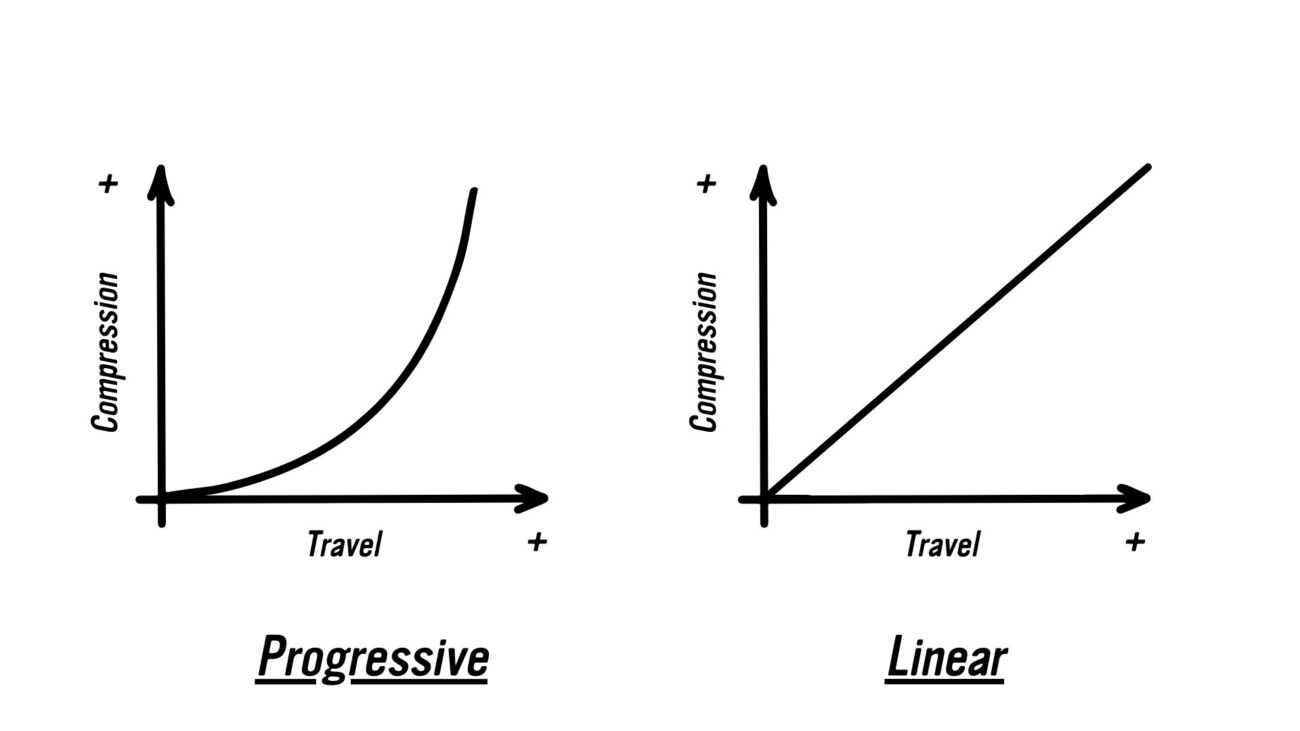

Coil rear mountain bike shocks are great, but the linear curve does mean they don’t stiffen up at the end.

“Linear” means that the shock gets stiffer in proportion with the compression.

“Progressive” means that the shock gets stiffer at a rate that’s higher than the compression.

“Bottom out” is the point at that you reach the very end of the shock’s stroke and run out of travel to compress.

The Starling’s steel swing arm means that there’s no harsh, clangy bottom out, but you might feel it through your feet on big hits. Coil shocks employ simple solutions to resolve this; rubber bumpers or hydraulic bottom outs.

Many bike companies say that a progressive suspension gives good ‘pop’.

This just isn’t the case, ‘pop’ comes from good mid-stroke support (probably just a bit past sag point), something linear suspension and coil is very good at. If you were to optimise progressive suspension for mid-stroke support, you’d have to up your spring rate and it would be way too stiff at the end stroke and you wouldn’t get full stroke.

So where does the Cane Creek Tigon come into this?

The Tigon rear shock uses a low-pressure air shock in parallel to the coil spring to increase spring rate as you move towards the end of the travel. This allows the benefits of coil whilst also allowing the shock to ramp-up, giving a smoother transition to the end-stroke compared to a classic coil shock.

The Cane Creek Tigon also allows you to easily tune the amount of ramp-up, by adjusting the air pressure. Finally, since the air pressure is so low, <30psi, there is minimal extra pressure on the seals, meaning minimal friction.

So, is the Cane Creek Tigon the perfect rear shock for single-pivot mountain bikes?

First, I actually don’t think that ramp-up is an issue. The shocks we spec work brilliantly with our frames and there’s no ill effects of using a linear coil damper with our single pivot, steel design.

But – if you’re still put off and would like more tuneability, the ability to vary your rate of ramp-up and a more progressive feel then the Cane Creek Tigon looks to be a great option.

Available Now With Tigon Shock

And we’ve now created a limited edition, top-spec super build – all geared around the new Cane Creek Tigon shock.

Available for Murmur and Twist, the Starling Cycles Cane Creek Tigon Limited Edition is a complete bike, supplied with a Helm Fork, Middleburn crankset, Hope components, Starling Pro Wheels (Hope, DT, Sapim) and Shimano. And, of course, the new Tigon. And if that’s not quite high-end enough, you’ve got the option to upgrade to eeWing cranks.

You can learn more about this super limited edition build here.